Companies whose manufactured products and processes, such as those in life sciences (medical devices, pharmaceutical, biotechnology, biopharmaceutical), aerospace, food and beverage, and some chemical companies, are increasingly regulated by government agencies.

These manufacturing companies must keep detailed records of their design, inventory, and product manufacturing processes. Current practice in many of these regulated industries is to maintain paper records of all information pertaining to the manufacture of their products.

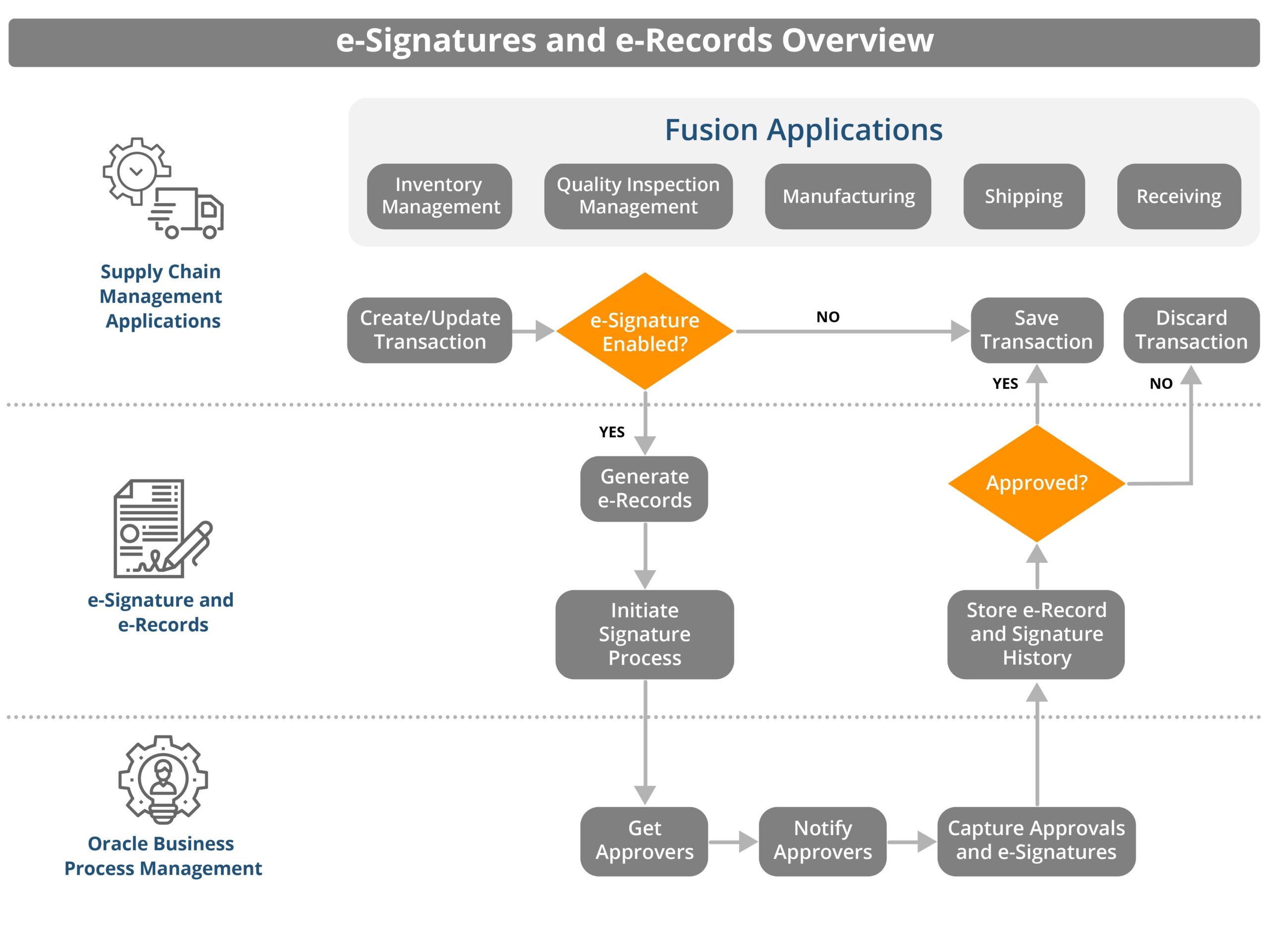

More companies want to maintain and store these records in electronic format to reduce this paperwork burden. This helps manufacturing companies to achieve compliance with the US Food and Drug Administration’s (FDA) 21 CFR Part 11 regulations. Oracle for Electronic Signatures and Electronic Records provides a configurable framework for securely capturing, storing, retrieving, and printing electronic records and signatures.

Critical business events for Oracle Supply Chain Management have been enabled in the areas of product design, inventory, manufacturing, quality, purchasing, and shipping.

From a manufacturing perspective, it allows you to enable electronic records and electronic signatures for the following in Oracle Manufacturing Cloud:

• Manufacturing Standard Operation Management

• Work Order Material Transactions

• Work Order Operation Transactions, and

• Orderless Transactions

Using this feature, you can review electronic records that are generated automatically and capture electronic signatures inline for standard operations and work execution transactions. And in addition, you can search and retrieve the related E-records through the electronic records work area.

Explore the Oracle Cloud Transformation case study and other case studies on migration to Oracle Cloud, Oracle Fusion Cloud, etc. here!

Standard Operation:

The E-record that is automatically generated for a standard operation contains the following information:

• Standard operation details

• Resource details

• Alternate resource details.

Work Order Material Transactions:

The E-record that is automatically generated for a work order material issue or return transaction contains the following information:

• Work order details

• Operation details, and

• Material transaction details along with material lot and serial details

The process to generate an electronic record and capture electronic signatures is initiated only when an operation transaction is submitted using Quick Complete or Complete with Details actions in the review dispatch list page or manage supplier operations page.

Work Order Operation Transactions:

The E-record that is automatically generated for a work order operation transaction contains the following information:

• Work order details

• Operation details

• Inspection details

• Operation transaction details

• Product transaction details with product lot and serial details

• Backflush material details with the material lot and serial details

Also, it’s important to note if multiple transactions such as complete, scrap and reject are reported through a single user action, then a single electronic record is generated that contains the details of all the transactions reported.

Orderless Transactions

The E-record that is automatically generated for an orderless completion or return transaction contains the following information:

• Orderless transaction details

• Inventory transaction details along with product lot and serial details, and

• Backflush material details along with material lot and serial details

As discussed earlier, once you enable E-signatures and E-Records for standard operations management and work execution transactions, the inline E-signature capture process is initiated when the transaction is submitted for approval. E-Records are generated, and the electronic signatures are captured before the transaction is saved. Notifications are sent to the approvers, which can be accessed through the bell notifications in the oracle cloud application or through e-mail. The approvers can review the E- records before adding their E- signature. Approvers can input their comments, indicate their approval or rejection and sign the E- record by entering their password.

The approvers also have the visibility to the current status of the approval process through the approval history region in the inline signature capture page and in the notifications.

Depending upon the outcome of the approval, the standard operation creation or update or the work execution transaction is either saved or rolled back.

You can search and retrieve electronic records in the e-records work area using multiple search criteria like the contents of the report title, the transaction type, organization, last signed date and status. The E- records are stored in a secured document repository and cannot be modified or deleted. Oracle E-signatures and E-Records stores both the approved and rejected records.